Planned Preventative Maintenance (PPM)

On Tap Services is known for reliable and efficient service for reactive maintenance across a number of capabilities, however; something we have been working on for quite some time is the implementation and roll out of our comprehensive yet succinct Planned Preventative Maintenance (PPM) Program across both Plumbing and Electrical divisions.

We know that effective and well managed preventative maintenance increases productivity by reducing the amount of reactive work and ensures early identification of problems. Further to this, our proactive maintenance approach provides the following benefits to our existing Client base:

- Increased efficiency and reduced risk of interruption;

- Extended asset life

- Prevention of damage to other essential equipment;

- Better budget management;

- Enhanced health and safety compliance; and

- Water and energy conservation.

Our key PPM capabilities include:

- Asset management planning;

- Lifecycle maintenance – optimising performance of assets for better value chain management;

- Statutory maintenance – ensuring building and services meets and maintains compliance with applicable regulations and legislation;

- Condition assessments and criticality analysis;

- System failure analysis and solutions; and

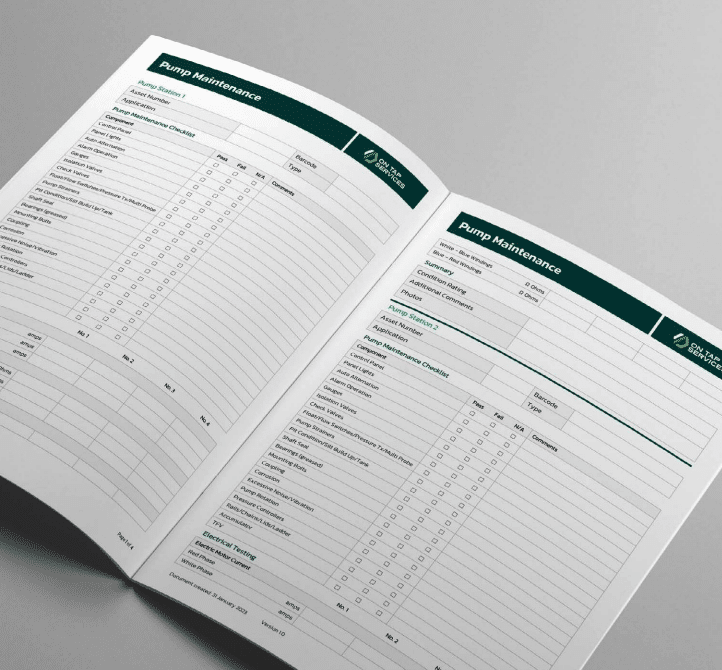

- Comprehensive reporting.

Our Client’s business continuity and ensuring their equipment is in safe working order is our top priority. Whether it be for Plumbing, Electrical or both, we can easily adjust our PPM Program as required. Our detailed maintenance planning and scheduling include inspections, cleaning, testing, and servicing:

Light Audit and lamp replacement

Light Audit and lamp replacement

Light Audit and lamp replacement

Thermographic scanning

Thermographic scanning

Thermographic scanning

RCD Testing

RCD Testing

RCD Testing

Emergency lighting

Emergency lighting

Emergency lighting

Grease Arrestors

Grease Arrestors

Grease Arrestors

Pumps and Pump Systems

Pumps and Pump Systems

Pumps and Pump Systems

Emergency Eyewash/Showers

Emergency Eyewash/Showers

Emergency Eyewash/Showers

Water filtration

Water filtration

Water filtration

Hot Water Systems

Hot Water Systems

Hot Water Systems

Backflow Prevention

Backflow Prevention

Backflow Prevention

Bathroom and general plumbing inspections

Bathroom and general plumbing inspections

Bathroom and general plumbing inspections

Testing and tagging

Testing and tagging